To produce them, it is necessary to go through many meticulous and rigorous stages to turn from raw rubber materials into high-quality products. Do you know how this process works? Together with Nam Long to figure out the basic steps to create a pair of rubber gloves.

1. WHY RUBBER IS A POPULAR MATERIAL FOR MANUFACTURING PROTECTIVE GLOVES?

Nowadays, you can see that rubber gloves are applied in many different fields like household, cut-resistance, anti-chemical, medical, aesthetics and so on. So why is this material so "prioritized"?

Waterproof

Water is the cause of many skin problems, which affects our health, especially the impacts of detergents. Many people assume that they don't care about this advantage of rubber gloves until they have problems with water.

Anti-bacterial

As you can see, natural rubber is derived from the resin of rubber tree, which is resistant to most chemicals, acids, bases, chlorine, iodine, and formaldehyde. When using natural rubber to produce gloves, it will become a comprehensive-protective barrier. That's why you could see that latex gloves are used to prevent bacteria from spreading.

High puncture-resistance

One of the advantages of rubber is its thickness, elasticity, and puncture-resistance that are many times higher than other materials such as wool, cotton, vinyl, plastic, and so on. This helps them to protect the users' hands from external agents, especially sharp objects. For the high-level of sharp objects, rubber will be combined with other materials to increase the level of protection.

Comfortable for using

The great elasticity of rubber will help your hands more flexible. Precisely, natural rubber could create a true-feeling, which is extremely important for fields that require dexterity such as surgery, aesthetics, tattoos, etc. To bring comfort to users, many manufacturers have integrated with modern technology like anti-sticky, anti-bacterial, deodorant treatments, and so on.

Inherent natural materials

Vietnam is one of the countries with potential rubber, therefore, it is very advantageous to produce protective rubber gloves. Besides, this also affects the price of products; a pair of regular household rubber gloves is extremely cheap for everyone.

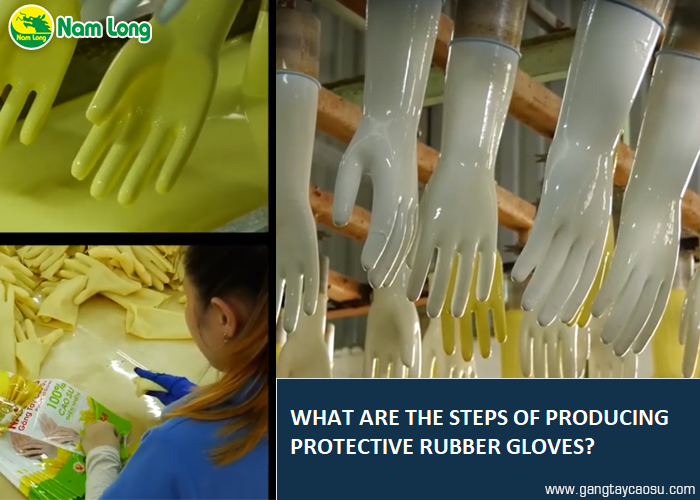

2. WHAT ARE THE STEPS OF PRODUCING PROTECTIVE RUBBER GLOVES?

Rubber gloves are popular protective equipment nowadays. They can be the household gloves for you to wash dishes and clothes or they can be used in gardening, food processing, medical, tattoo, and so on. However, not many people know about the producing process of rubber gloves. To help you understand this process, Nam Long will show the basic steps of producing a pair of regular rubber gloves.

Step 1: Cleaning the molds

First, to produce a pair of rubber gloves, you need a mold (glove-shaped) made of ceramic or aluminum. In some factories, they will install a consecutive mold-production-line.

Before the next step, these molds are cleaned to ensure that all dust and residues are removed from previous production runs because a small impurity can also create an error in the glove manufacturing process. Precisely, they are washed with soap and dipped into bleach to remove impurities on the molds, even the smallest ones.

After that, the molds will be cleaned continuously with an automatic rotating brush. The small-stiff hairs of the rotating brush will clean lines of the molds' fingers. After a thorough scrubbing, the molds will be doused with hot water and dried.

Step 2: Creating a thin layer

After being cleaned, the molds will be dipped into the chemical tank. The chemical adheres to the molds and forms a thin layer on the surface. This is a very important step because the thin rubber layer cannot cling to the molds without this chemical layer. You can assure that this chemical film will be removed after the process is completed.

Step 3: Forming rubber gloves

In the next step, the molds are put into a warm-liquid rubber tank. The rubber has been enhanced its durability. After being coated with a rubber layer, the molds are rotated on the shelves to remove any drops of liquid rubber before putting them into the oven. The coverage depends on the rubber type. The medical gloves are usually thinner than the household ones. Under high temperatures, the thin rubber layer is dried and formed into gloves.

If the gloves are made of synthetic rubber, they will be pulled out of the molds manually because they are more adhesive than the natural rubber. Whereas, gloves made of natural rubber are easier to remove with automatic air blowers.

For the household gloves, many manufacturers add some steps of creating edges, painting colors, and using anti-bacterial, anti-adhesion, deodorant treatments to bring the best product to users. Some other specialized gloves will be combined with more different stages.

Step 4: Checking the products

The finished gloves are put into testing. At this time, the workers will stretch, pump water and blow air into the gloves to check whether they have errors or not such as puncture, tear, or even the smallest holes. If there is no problem, they will be packed, sealed and distributed to the markets. For medical latex gloves, they will need to be coated with a layer of cornflour for them not to stick together. For household rubber gloves, they will be packed without using cornflour.

Thus, to produce a pair of protective rubber gloves, there are not many steps. However, each step requires high meticulousness and stringency. The above steps are only a basic manufacturing process of rubber gloves that you can get a simple understanding. They will be integrated with different steps to create suitable products for each glove line.

>>> See more: How much are rubber gloves? Where can we buy the authentic and high quality ones?

Please contact us:

Address: 103 Tran Van Kieu Str, Ward 10, District 6, Ho Chi Minh City.

Email: namlongco.gloves@gmail.com

Tel: (+84)28.3755.4772 – (+84)983.101.434